Description

Pipesim 2024 Features

Dual-string tubing configuration

In Pipesim 2024.1, the advanced well functionality is extended to support wells with a dual string configuration, in which a pair of two parallel tubing strings are installed in the same wellbore, to enable production from or injecting to isolated zones that cannot flow simultaneously into a single tubing string.

Upgrade of the Olga S flow model to the version from Olga 2023.1

The list of available flow correlations in the Pipesim simulator is updated to include the version of the Olga S flow model from Olga 2023.1, with support for the high-definition (HD) model. The HD model represents a step-change in the fidelity of multiphase flow modeling and is a result of over 15 years of industry-sponsored research.

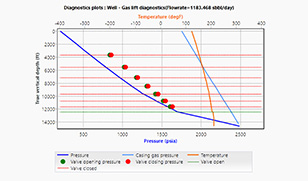

Gas lift design report

In Pipesim 2024.1, you have an option to generate a PDF report with all gas lift design input parameters and output results, including the comprehensive gas lift design plot. The report header includes user-defined data such as company, field, well, etc.

Upgrade of the simulation results’ file format

To reduce the size of simulation result files that are stored in the pipr folder, Pipesim 2024.1 uses a new file format. This means that if you open a previously saved model using 2024.1, you will notice that the results in the new version are not displayed by default. A quick re-run is needed to visualize the results again

Continuous innovation incorporating leading science

For over 30 years, the Pipesim simulator has been continuously improved by incorporating not only the latest science in the three core areas of flow modeling—multiphase flow, heat transfer, and fluid behavior—but also the latest innovations in computing, and oil and gas industry technologies. The simulator includes advanced three-phase mechanistic models, enhancements to heat transfer modeling, and comprehensive PVT modeling options. The ESRI-supported GIS map canvas helps deliver true spatial representation of wells, equipment, and networks. Networks can be built on the GIS canvas or generated automatically using a GIS shape file. The interactive graphical wellbore enables rapid well model building and analysis. Faster simulation runtime has also been achieved for all modeling though the implementation of a new parallel network solver to spread the computational load across all processors.

Steady-state flow assurance, from concept to operations

The Pipesim simulator offers the industry’s most comprehensive steady-state flow assurance workflows for front-end system design and production operations. The flow assurance capabilities of the simulator enable engineers to ensure safe and effective fluid transport—from sizing of facilities, pipelines, and lift systems, to ensuring effective liquids and solids management, to well and pipeline integrity. Shared heat transfer, multiphase flow, and fluid behavior methodologies ensure data quality and consistency between the steady-state and transient analyses.

Ensuring Safe and Beneficial Liquid Transfers: Modern manufacturing systems require designs that ensure liquids are transported safely and efficiently from process tanks to process equipment. Whether these systems exist in difficult environments, such as deep-water areas with complex infrastructure, or in large docks, adds many factors to such plans. The correct simulation capability of a wide range of scenarios and conditions is applied to the PIPESIM steady-state multiphase simulator, which is used as a forward-flow simulator in the design of production systems.

Production optimization: When a system is manufactured, reliability of optimal production is critical to achieving maximum economic potential. In this regard, PIPESIM software provides a complete set of workflows – from the right choice to the task to the determination and migration of the challenges of flow assurance and even the online optimization of the completed system.

Multiphase Flow Simulator, Steady State: PIPESIM software is a multiphase, steady state simulator. PIPESIM models the multi-phase flow from the reservoir to the source and source. The efficiency of flow and surface equipment can be calculated to produce complete manufacturing system analyzes. PIPESIM software can be integrated with Petrel E&P and Avocet’s production operating software platform to provide a single solution and complete simulation from repositories to production

Safe and effective fluid transport

Modern production systems require designs that ensure safe and cost-effective transportation of fluids from the reservoir to the processing facilities. Once these systems are brought into production, the ability to ensure optimal flow is critical to maximizing economic potential. From complex individual wells to vast production networks, the Pipesim steady-state multiphase flow simulator enables production optimization over the complete lifecycle.

Continuous innovation incorporating leading science

For over 30 years, the Pipesim simulator has been continuously improved by incorporating not only the latest science in the three core areas of flow modeling—multiphase flow, heat transfer, and fluid behavior—but also the latest innovations in computing, and oil and gas industry technologies. The simulator includes advanced three-phase mechanistic models, enhancements to heat transfer modeling, and comprehensive PVT modeling options. The ESRI-supported GIS map canvas helps deliver true spatial representation of wells, equipment, and networks. Networks can be built on the GIS canvas or generated automatically using a GIS shape file. The interactive graphical wellbore enables rapid well model building and analysis. Faster simulation runtime has also been achieved for all modeling though the implementation of a new parallel network solver to spread the computational load across all processors.

Steady-state flow assurance, from concept to operations

The Pipesim simulator offers the industry’s most comprehensive steady-state flow assurance workflows for front-end system design and production operations. The flow assurance capabilities of the simulator enable engineers to ensure safe and effective fluid transport—from sizing of facilities, pipelines, and lift systems, to ensuring effective liquids and solids management, to well and pipeline integrity. Shared heat transfer, multiphase flow, and fluid behavior methodologies ensure data quality and consistency between the steady-state and transient analyses.

New well type: advanced

A new advanced well type to support complex well configurations. This includes a limited edition of this functionality, enabling modeling of: flow control valve, tail pipe, tubing and annulus flow with two surface pressure conditions, ESP separated gas in the annulus, steam circulation with or without completion, and production/injection pairs using the same well perspective.

Smart well completions with flow control valve (FCV)

Modeling of FCVs is introduced under the advanced well editor. The flow in the annulus is modeled and the number of FCVs is not limited or related to the number of completions in the model. The FCV catalog is updated with all SLB valves, with the option to add a custom valve from other manufacturers.

Enable phase ratio override on Multiflash PVT files

Phase ratio override is the ability to change gas and water ratios at any stream inlet and neglect the phase ratios specified or calculated in the original fluid description. This feature is enabled to facilitate, in addition to overriding phase ratio in completions, the fluid editor and in sources, generating vertical flow performance (VFP) files while a Multiflash (MFL) file is used in the model.

New GIS map backgrounds

To improve the visualization on the GIS canvas, three background modes are added to the list of base maps: white, light, and dark. These backgrounds enable the display of better contrast of the network model objects and results and hide geographical data.

Contact email for obtaining software installation package: gosoftvip@163.com The resources are sourced from the internet, and this introduction is for learning purposes. If there is any infringement, please contact us for deletion!

For more info write me

Email : gosoftvip@163.com

telegram : @sacyou888